Technological support

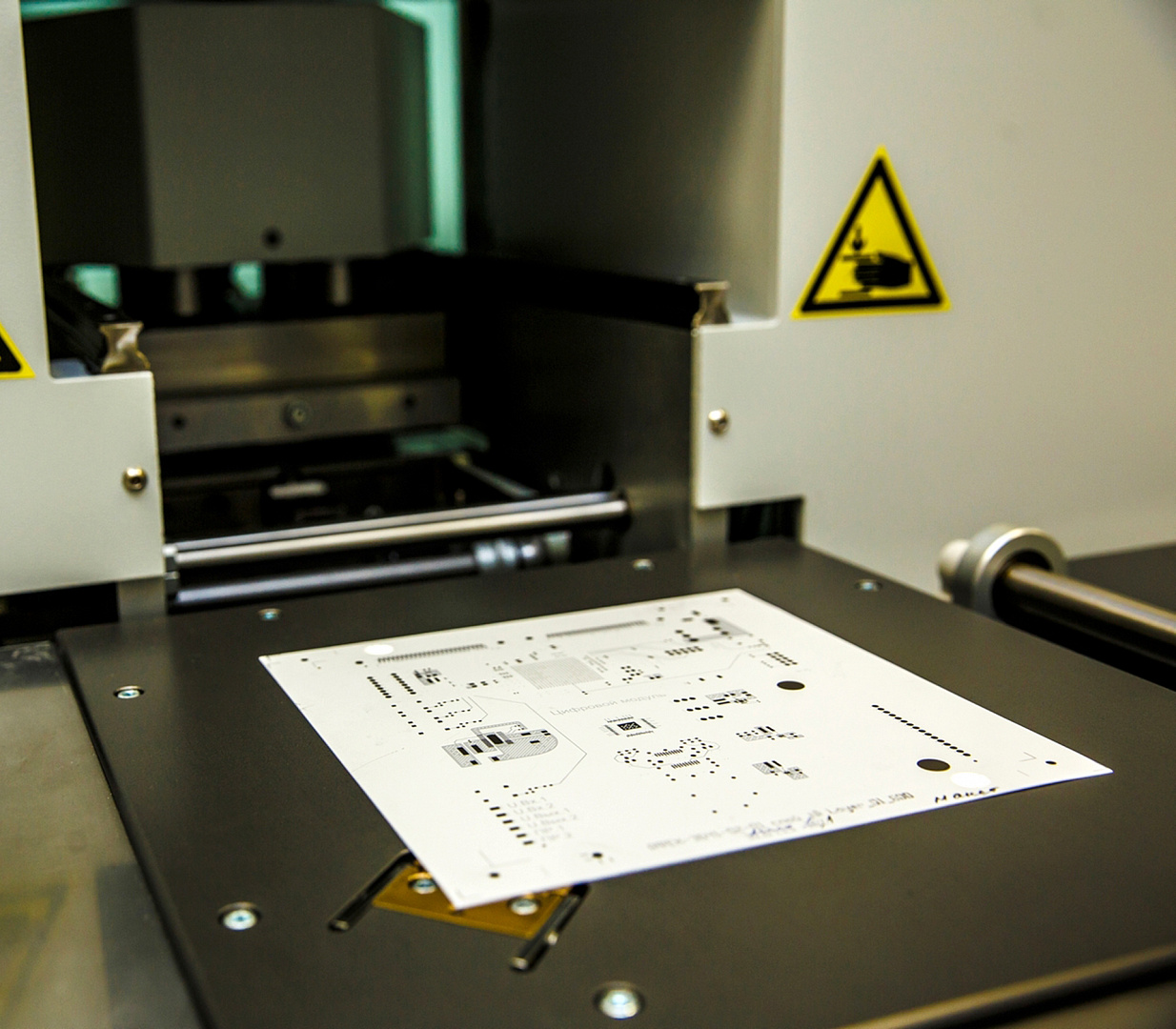

Mounting of the components on printed board

Automatic and semi-automatic mounting of the entire range surface-mounted electronic components on printed circuit board assemblies (PCBA) of any complexity using both standard methods of mounting electronic components and innovative technologies:

- single- and double-sided surface mounting of SMD- components, supplied in a tape, small container, matrix-like tray

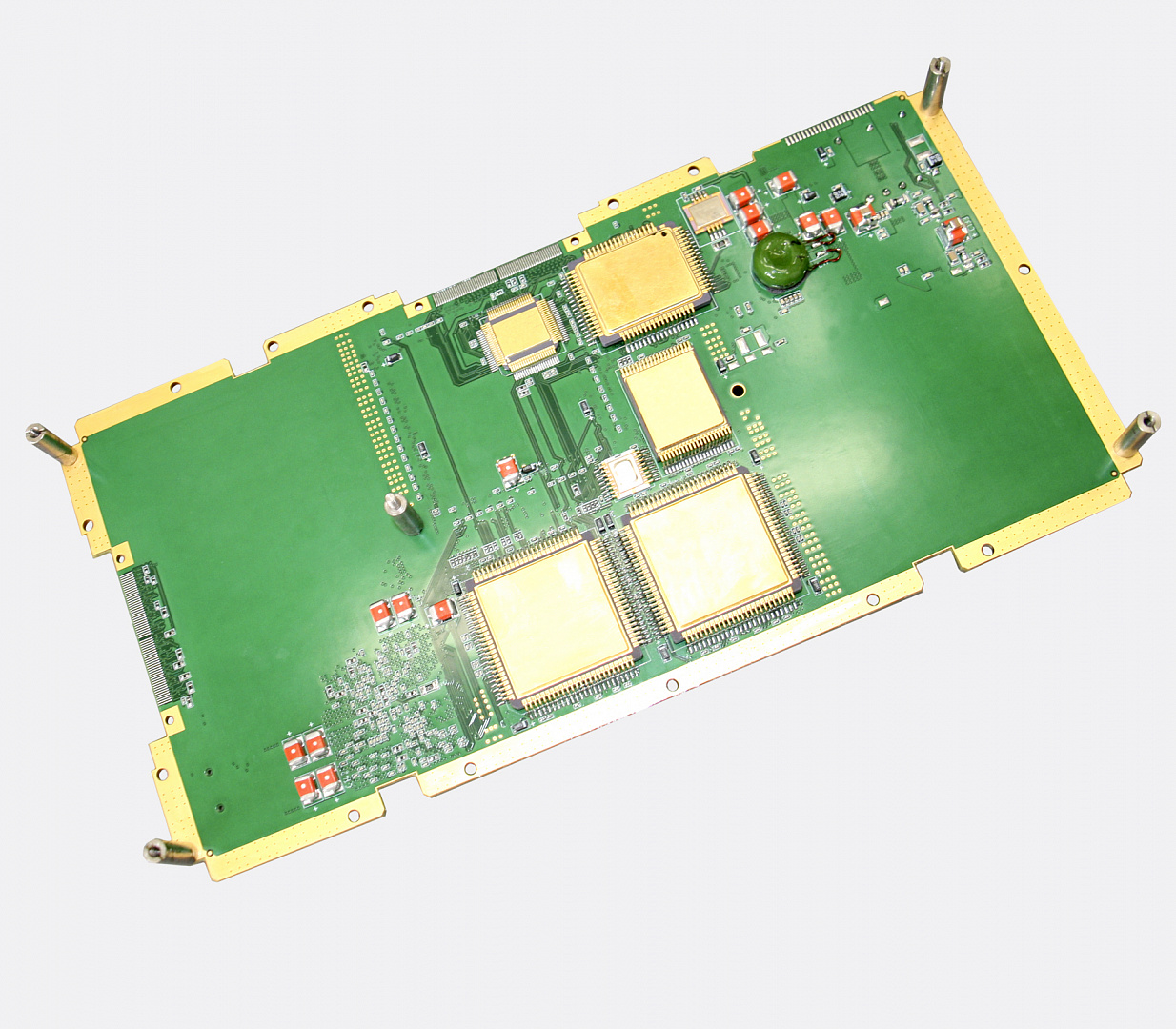

- types of mounted components: CHIP, SO, SOT, SOD, SOIC, TSOP, SOJ, PLCC, QFP, BGA, µBGA, CSP, CGA, LGA, SMT-connectors and others

- overall dimensions of printed board assemblies - up to 400x300 mm

- package height – up to 40 mm

- minimum dimensions of ECB (electronic component base) – 01005

- minimum distance between contact pads - 0.3 mm

- CHIP-components size - from 0201

- minimum pin pitch of Quad Flat Package-components – 0.4 mm

- minimum pitch of ball leads of BGA components – 0.5 mm

- disassembly of IC from the BGA, QFN packages and so on

- recovery of ball leads of BGA IC (reballing)

- selective mounting of selected components, inserted into holes

Quality control

- optical inspection

- X-ray control

- electronic monitoring, including

- electro control, including boundary scan (JTAG-control), both during manufacturing radio-electronic equipment, and in carrying out quality control of products, whose assemblies have been completed at third-party enterprises

Repairs of PCB assemblies

Repairs of PCB assemblies with components, mounted in BGA, CGA, LGA, QFN, etc. packages; conducting ball lead recovery operations (reballing), as well as the ability to perform mounting IC on PC board by means of hard-alloy balls.

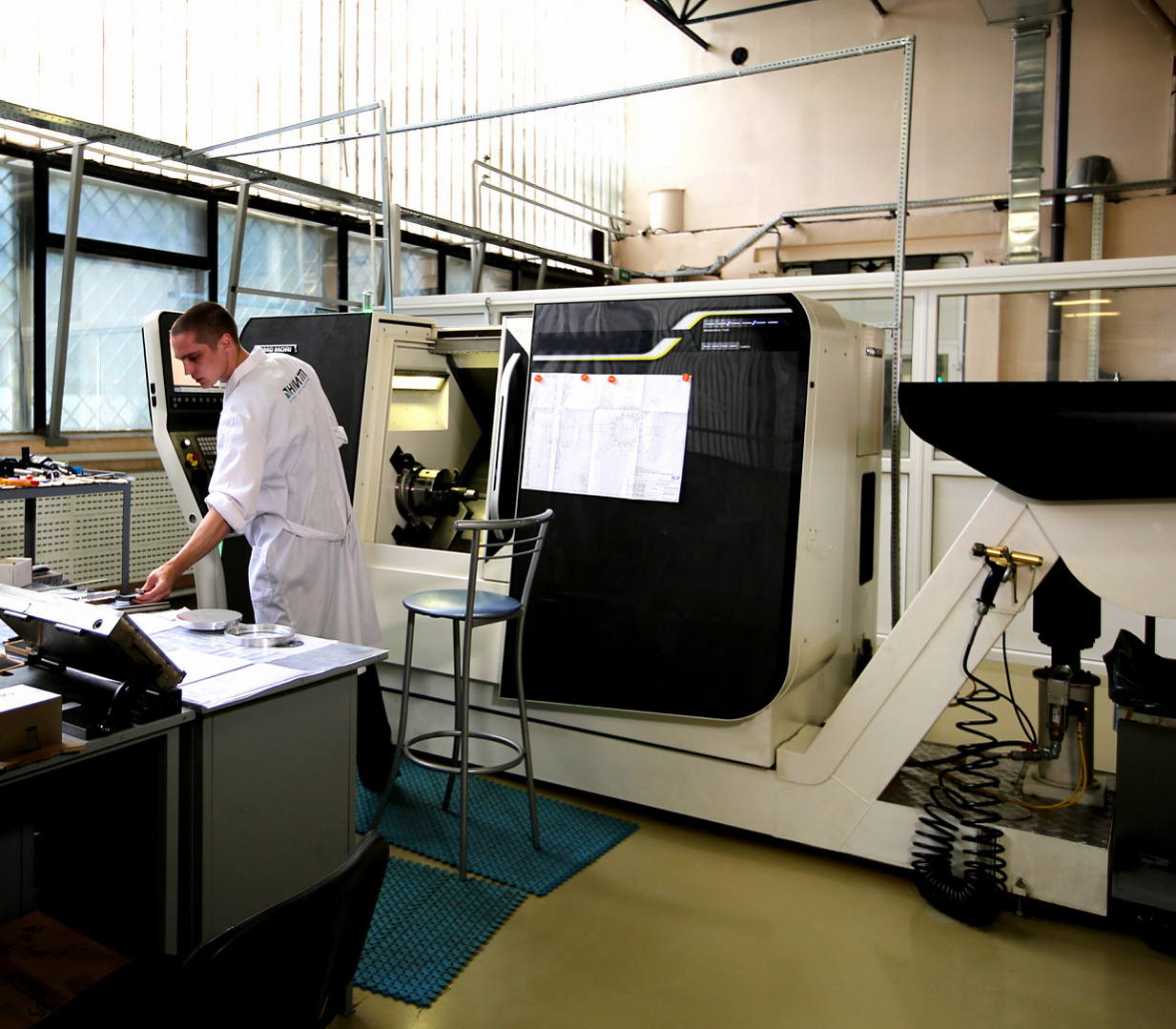

Section for surface mounting is equipped with the most up-to-date equipment of the leading manufacturers, which allows performing automatic and semi-automatic mounting SMD-components on PCB with high quality.