LTCC进口替代

Our Institute is currently conducting extensive researches on domestic ceramic materials for fabricating products using LTCC technology.

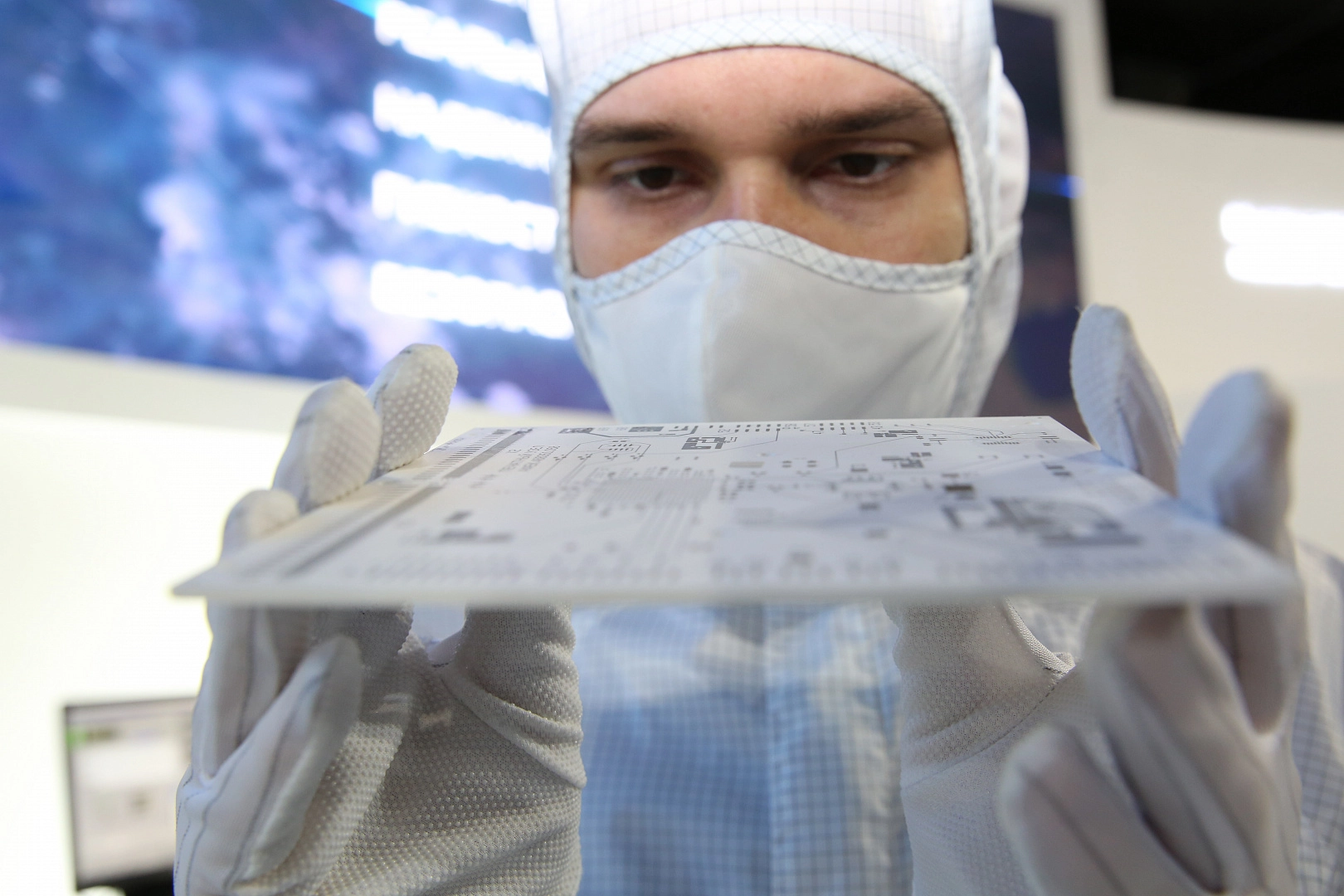

The fabrication of LTCC technology-based Multilayer Ceramic Circuit Boards (MCCB) is one of the most promising development trends of the electronics industry.

A unique set of physical and electrical properties of these products, such as low coefficient of thermal expansion, tightness, thermal conductivity, etc., allows for satisfying the most sophisticated and specific needs of the aerospace sector.

Since 2014, RIPI has been actively using the technology of low-temperature co-fired ceramic (LTCC) for its production needs. Conductive pastes and ceramics are applied as the main structural materials.

Valery Khodzhaev, chief technologist of our Institute, said of these researches:

- We’ve developed a wide range of MCCBs for secondary power supply units mounted within the onboard radio and telecommunications equipment, manufactured by RIPI. Recently, we’ve been experiencing certain difficulties in manufacturing MCCBs, foremost among which is application of imported structural materials that are expensive and difficult to access. To reduce our enterprise’s costs for the purchase of the materials, optimization in logistics, it was decided to replace the imported structural materials for LTCC with the home-produced ones.

The results of various studies and researches, undertaken at RIPI over past years, have made it possible to produce a multi-chip module and a controller’s universal computing module, where a domestic complex of jointly sintered ceramics and pastes is used. Currently, the foreign heat-conducting composite materials applied for PCBs have been replaced with home-made low-temperature ceramics LTCC or with its more complete analogue on a metal substrate.

RIPI Press Service